Stack Light

The XL2 Noise and Vibration Analyzer in combination with this Stack Light provides a turnkey solution for noise level monitoring or

pass / fail measurements where a prominent visual indication is required. The Stack Light connects directly to the XL2 Analyzer and shows the actual measurement result with three different colors; green, orange and red.

Product Data

Digital I/O Adapter PCB

For automated operation with external peripheral devices the XL2 Analyzer can be linked into a programmable logic controller. The Digital I/O Adapter is tailored for rail mounting in electric switch boxes.

Product Data

Auto-start Function

Measurement starts by automatic level trigger, external foot switch or instrument start button.

Tolerance Management

Tolerance curves can either be imported from txt-files or directly derived from captured measurements. The XL2 calculates tolerance bands based on

- Single captured results

- txt-files manually generated on the PC

- Mean average of multiple captures

- Min/Max curves of multiple captures

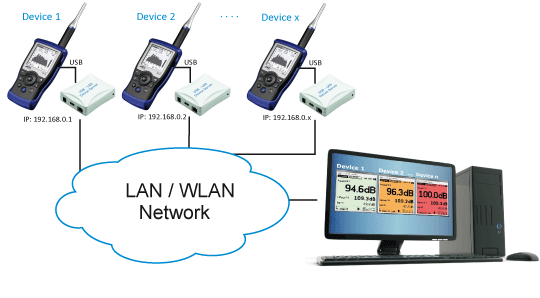

Remote Monitoring

Multiple XL2 Analyzers connect with USB Device Servers to a network for online condition monitoring. Wireless solutions are also supported. An individual Projector PRO Software may be started for each XL2 Analyzer, thus simultaneously displaying all XL2 screens on the PC monitor. Each XL2 Analyzer can be controlled from the host PC.

Individual Solution programmed by Customer

The Remote Measurement Option allows querying of the XL2 measurement data online via the USB interface. Multiple XL2 Analyzers can be implemented into a customer specific solution for quality control. The XL2 acts as a front end device for precise measurements.