- Home

- APPLICATIONS

- QUALITY CONTROL

- DIGITAL MEMS MICROPHONE

Digital MEMS Microphone

Digital MEMS (MicroElectroMechanical System) microphones are components that are used in various consumer devices as well as in automotive and industrial applications. A digital MEMS microphone combines an acoustic sensor as well as an A to D converter on one silicon chip. This requires only a very small footprint on a PCB (printed circuit board), and allows the microphones to be connected directly to a signal processor.

Due to the rapidly-growing use of voice recognition applications, digital MEMS microphones are often used in an array formation. To ensure flawless operation, the absolute specification values, and, even more important, the values of all microphones in the array relative to each other must be tested. This page explains how to interface digital MEMS microphones to an acoustic test system and how to measure the relevant key parameters for a reliable QC procedure.

- For measurements on single components or arrays of digital MEMS microphones

- Seamless integration into NTi Audio microphone test solution

- Provides different voltage supplies and operating clock frequencies

What to test

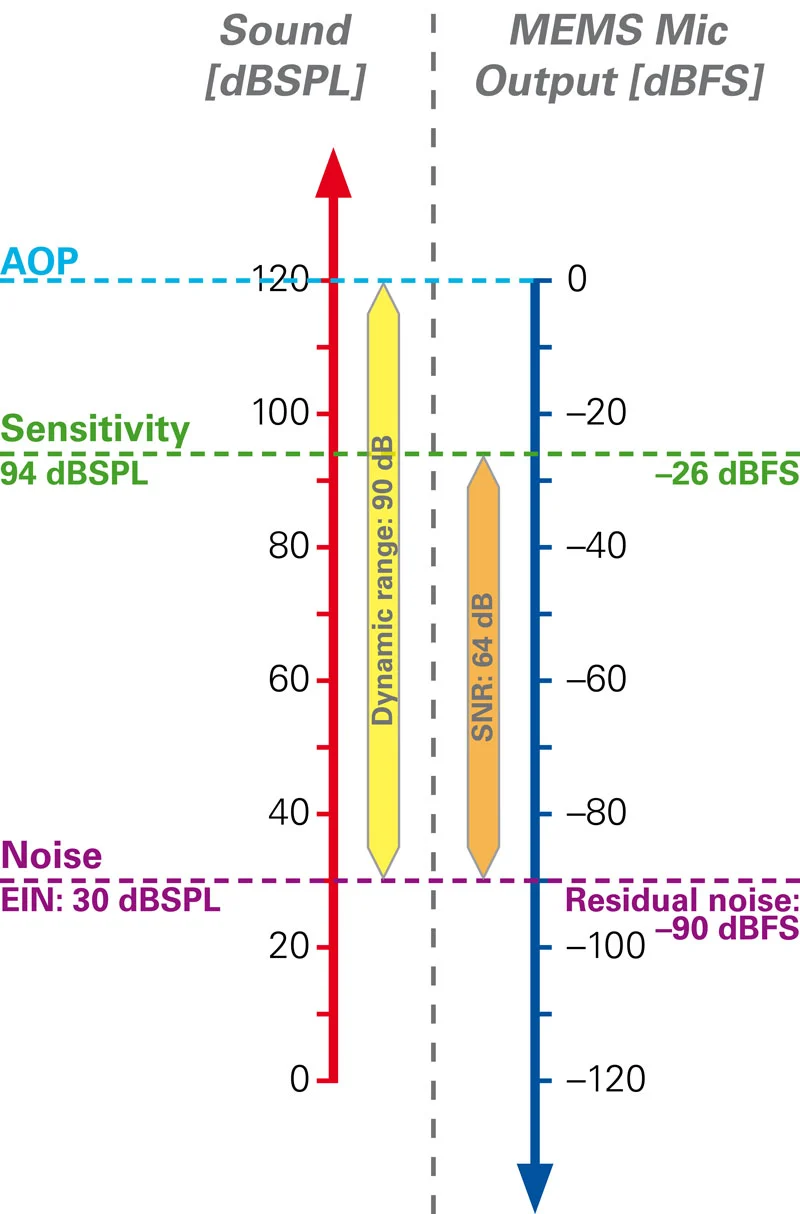

To test the acoustic parameters of a digital MEMS microphone, the digital signal must interface directly with the audio analyzer system, or be converted to a different format, e.g. analog. The typical parameters of interest for a QC test are the same as for the testing of most other microphones; Sensitivity, Frequency response, Distortion, and sometimes Signal to Noise ratio (SNR). For a complete microphone characterization typically performed in a lab environment, parameters such as EIN (Equivalent Input Noise), PSR (Power Supply Rejection), PSRR (Power Supply Rejection Rate), and Dynamic Range are measured or calculated. Optionally, the directional behavior of a microphone at different frequencies can be measured by using a turntable.

For all absolute measurements (those that are not expressed in % or dB) the units for digital MEMS microphones are different. While the sensitivity of analog microphones is expressed in mV/Pa or dBV/Pa, the unit for digital microphone is dBFs. This stands for “decibels below Fullscale” and describes the headroom of a digital microphone from 94dBSPL (1Pa) to the maximum digital output of that microphone. This point of maximum digital output is also referred to as the AOP (Acoustic Overload Point).

Acoustic vs. Digital Observation

Testing single MEMS microphones is very rare. In most cases, the MEMS microphones are tested on an assembled PCB containing several MEMS microphones. For characterizing the performance of that PCB, it is of interest how the assembled MEMS microphones behave relative to each other. A typical parameter is the “Sensitivity Span”; the difference between the highest and lowest sensitivity measured on the assembled MEMS microphones.

Digital MEMS microphone peculiarities

Digital MEMS microphones deliver data in the ½ cycle PDM format. The microphone requires a CLK input, and delivers its data on a DATA output. Furthermore, two microphones share one data line. Therefore, each microphone is configured to be either a “left” or “right” microphone. This is done by hardwiring the L/R input pin to either Vdd or ground. MEMS microphones are supplied mostly by 1.8V or 3.3V.

In normal operation, the “left” microphone writes a data bit on each rising edge of the clock signal, while the “right” microphone writes a data bit on each falling edge. While one microphone is writing data, the other one puts its DATA output into a high-impedance mode. On the DSP that is receiving the data, the left and right signal data are then separated and put together into two signal streams.

Configuration

Mobile Phone Test System

including

- Flexus FX100 Audio Analyzer

(includes FX-Control Software) - FX-SIP impedance module and amplifier

- Measurement Microphone M2010

- PureSound™ Option

(includes RT-Speaker Software)

- Flexus FX100 Audio Analyzer

Optional

- Environment Sensor

- Class 1 Sound Calibrator 94/114 dB

- FX100 Rack Mounting