- Home

- APPLICATIONS

- NOISE VIBRATION MEASUREMENTS

- STRUCTURAL VIBRATION MEASUREMENTS

Structural Vibration Measurements

Overview

When there is an extraordinary source of vibrations, such as a nearby construction site or adverse windy conditions, it is important to measure vibrations in structures, such as buildings and bridges, or on the ground. The reason is to ensure, at the least, that the vibrations do not cause discomfort to people in the vicinity and, more critically, do not damage the structure.

While every structure vibrates to a certain degree, limits should be monitored to ensure the integrity of the material used in the construction, as well as the well-being of people. Given these safety and comfort considerations, many countries have regulations and standards that define these vibration limits in different environments.

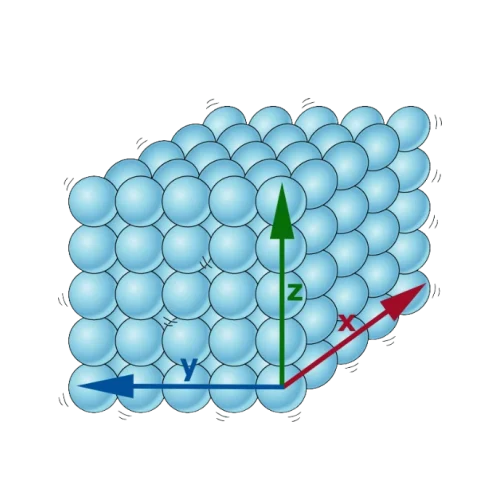

Structural vibration is defined by mechanical particle oscillations. These are measured in three perpendicular directions.

A Vibration Monitor is the most common tool for measuring vibration levels.

What is a Vibration Monitor?Where are Structural Vibrations measured?

Structural vibrations are measured in various environments, such as:

Construction Sites

Heavy machinery operations on construction sites, particularly excavation, pile driving, vibratory compacting, demolition, and movement of tracked equipment, will produce ground-borne vibrations, which can damage buildings in the neighborhood. Also disturbances to people during working and/or after hours may need to be regulated.

Blasting

Minimize the impact of activities on the surrounding environment, nearby communities, and safety of the workers, during blasting operations in the mining industry.

Rail and Road

At peak traffic times, building and ground vibration tracking may be necessary to ensure the comfort of residents in the neighborhood.

Tunnelling

The vibration generated during the construction of subway tunnels with a tunnel boring machine has a significant impact on the environment, particularly under a city. It is critical to monitor the foundation works above the tunnel.

Bridges

Structural responses to extreme natural and man-made events, as well as an increasing volume of users and vehicle sizes can lead to the sudden damage and collapse of bridge structures. Continuous or periodic assessment of the condition and performance is crucial in preventing bridge collapses.

Vibration Monitors have a wide range of further applications. They are employed in protecting sensitive structures, such as

- Hospitals

- Power stations

- Water dams

- Data centers

- Museums

- Historical sites

and in such diverse areas as

- Demolition

- Manufactured product testing

- Education

5GV

The 5GV is a cutting-edge MEMS vibration and tilt monitor delivering exceptional precision, combined with an integrated 4G gateway (optional Wi-Fi). It is ideally suited for structural health monitoring, protection of occupants inside buildings, and safeguarding sensitive equipment.

Designed with ease of use in mind, the 5GV is simple to configure, quick to install, and can be fully managed remotely—significantly reducing the need for time-consuming on-site visits. Its low-power architecture, together with flexible external power options, minimizes maintenance requirements and ensures reliable long-term operation.

With the follwing kit:

5GV three axis vibration monitor

Optional:

5GV tripod mounting plate (for temporary ground mounting)

Which units are used to measure vibrations?

During vibration, particles within the structure oscillate. For each axis, the speed (velocity) at which the particles oscillate is calculated from the distance moved (displacement) over time.

Particle Velocity (v), measured in mm/s or in/s, is defined as

v = Δd / Δt

Δd → the particle displacement in millimeters or inches

Δt → the time in seconds

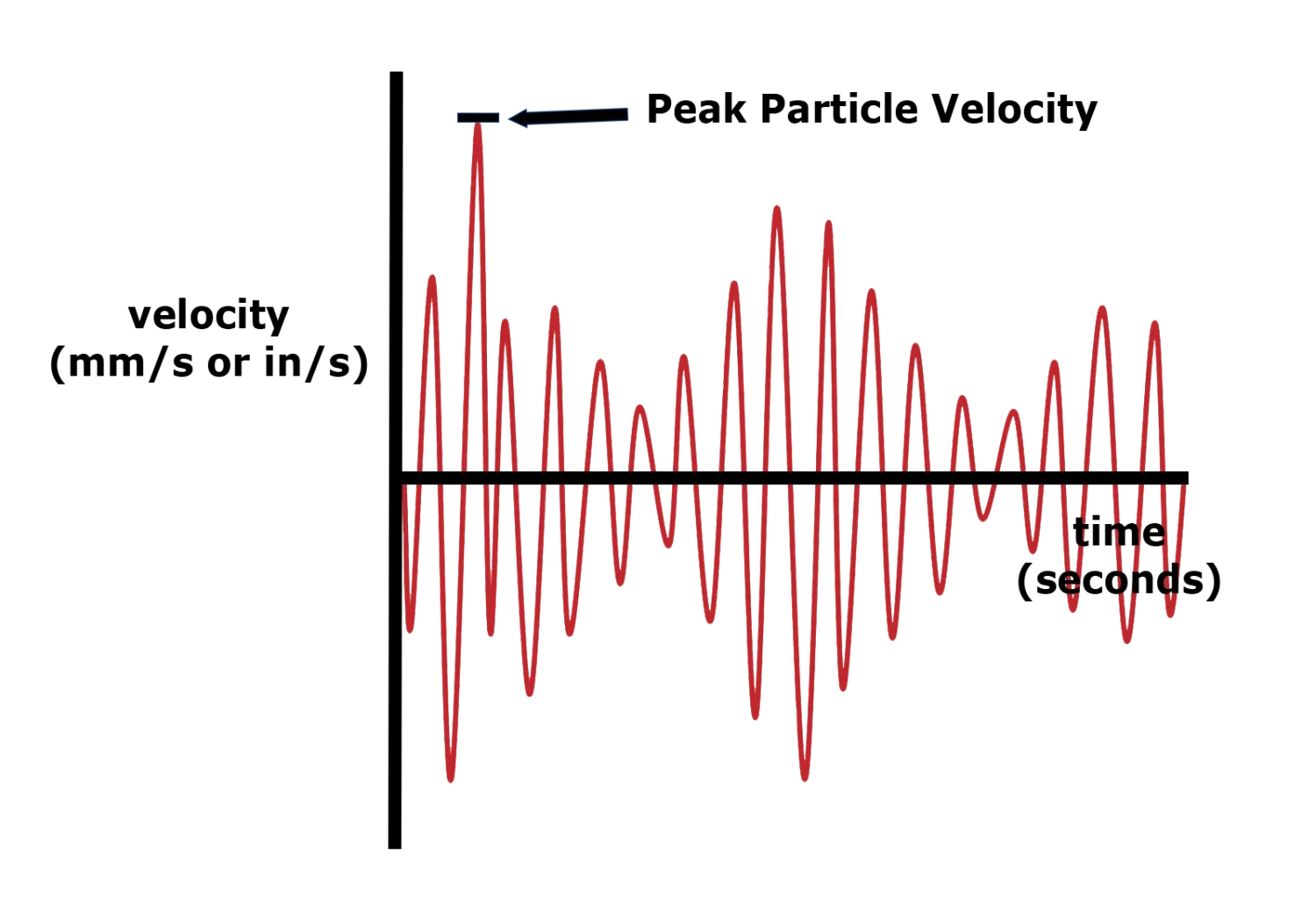

PPV (Peak Particle Velocity)

The PPV is the most basic value used in vibration measurements. It indicates the greatest particle velocity over a period of time per axis.

PPV is defined as the maximum absolute value of the unweighted signal

PCPV (Peak Component Particle Velocity)

The PCPV is the maximum of the three PPVs in each axis direction.

PCPV = max(PPVx, PPVy, PPVz)

PVS (Peak Vector Sum)

The PVS is the resulting velocity calculated by simultaneously considering the PPVs in all of the x, y, and z directions.

PVS = √((PPVx)2 + (PPVy)2 + (PPVz)2)

In words this is mathematically described as the square root of the sum of squares of the PPV components.

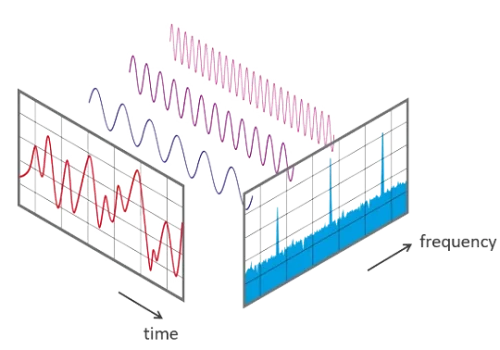

DF (Dominant Frequencies)

A vibration signal can be broken down into individual frequency components (using Zero Crossing* or Fast Fourier Transform methods). From this, the Dominant Frequencies (DF) can provide worthwhile information, such as a change in the natural (resonant) frequencies. These frequencies are proportional to a structure’s stiffness. A change, for example in a steel structure, can indicate serious corrosion. The monitoring of steel bridges should therefore alert on any shifts in the frequency’s values.

View of a signal in the time and frequency domain

* Zero Crossing (ZC) is the simplest method of frequency estimation. It works on the principle that, since an oscillation crosses the x-axis twice during each cycle, we can simply count the number of crossings and divide it by two and again divide it by the observation window size, giving us the Dominant Frequency. This method works better when we have a few complete cycles. The longer the length of the observation window, the greater is the accuracy.