Last week one of our product managers found himself crawling around the floor with a tape measure. In September 2017 a new EU directive came in to force, which regulates the noise created by vacuum cleaners. With particular reference to sound power level, we reviewed the directive.

One item caught my eye and the question follows, “How does one measure a maximum sound power level of 80 dB (A) and adhere to the directive?” In my opinion, the relevant themes are the test setup and the documentation. Below I have listed the most important points and simply explained what needs to be done to ensure that the noise from the vacuum cleaner you are testing is within the regulation.

First the definition: What is Sound Power?

Wikipedia offers a definition of Sound Power. In summary, the Sound Power Level LW characterizes the sound emissions of (i.e. the sound produced by) a sound source and is independent of the acoustic properties of the environment and also of the distance between the source and the measurement point. In contrast, the sound pressure level Lp describes the sound immission (i.e. the sound heard by an observer) at the measuring point.

The difference between sound power and sound pressure can be explained with an electric heater analogy: the heat output of a radiator is given in kW and thus describes the source. This is a constant value and corresponds to the Sound Power Level in the analogy. The temperature at a position in the room corresponds to the sound pressure in the analogy and depends on the distance between the source and the measurement point, the volume and insulating properties of the room and many other parameters.

How do I measure the noise of a vacuum cleaner and what do I need?

With a sound level meter, the emissions of a sound source, such as a vacuum cleaner in this case, can be determined quickly and easily. The sound power must be determined according to the specifications of the European Commission Regulation (EU) No 666/2013. That means that the sound power level shall be less than or equal to 80 dB(A). “sound power level” is defined as airborne acoustical noise emissions, expressed in dB(A) and rounded to the nearest integer. So, actually 80.4 dB(A) is still within the allowed limit.

Equipment you need:

- Sound Level Meter

- Measurement microphone

What does the test environment look like and how can I set it up myself?

There are several standards defined to determine the exact process to be followed during the measurement. These include ISO 3744 and IEC 60704-2-1:2014 as well as country-specific standards, such as ANSI-ASA S12.54 for America, DIN EN ISO 3744 for Germany and BS EN ISO 3744 for Britain. A comprehensive understanding of these standards as well as the EU Regulation 666/2013 is necessary for compliance.

I suggest you read and always refer to the standards. However, here are some tips to get you started:

The Test Environment

The test environment can be located indoors or outdoors. The ideal environment is on the ground in a large open space or hemi-anechoic chamber (free-field over a reflecting plane1). In an outdoor area, make sure it’s not too hot, too cold, too humid, too dry, windy, raining, snowing, etc. All of these could affect the sound produced and measured.

Precautions should be taken to eliminate any rattling due to nearby objects (e.g. furniture) or structures (e.g. windows) vibrating during the test.

To account for undesired reflections from nearby objects, walls and the ceiling, and for any residual background noises, measurement corrections should be applied.

The environment needs to have a constant, low background noise. Avoid loud environments and areas where impulsive noises, such as factory machines that switch on and off, passing cars, talking work colleagues, etc., are produced. If the background noise is too high or too impulsive, the environment is not suitable for the measurement of sound power level.

Also, avoid environmental conditions that could have an adverse effect on the microphones used for the measurements (e.g. strong electric or magnetic fields, wind, air blowing from the vacuum cleaner onto the microphone, high or low temperatures).

1) A free-field over a reflecting plane is a sound field region with a floor that reflects sound and with no adjacent reflecting surfaces. In practice, an acoustic free field is a field in which the influence of reflections at the boundaries or other disturbing objects is negligible over the frequency range of interest.

Ready for the Test

Prior to the first test on a new vacuum cleaner, run it with unrestricted air flow for at least 2 hours to ensure adequate running-in. For active nozzles, make sure that the agitation device is running but not in contact with the floor.

If necessary, empty the vacuum cleaner, also known as the Device Under Test (DUT), and clean the filters before you start. The same settings on the DUT should be used as were used during the dust pick-up on carpet test.2 Set the controls to the maximum position for normal operating. Close any of the bypass air openings that are used for reducing the suction power. If a boost function is available on the DUT, do not engage this during the measurement.

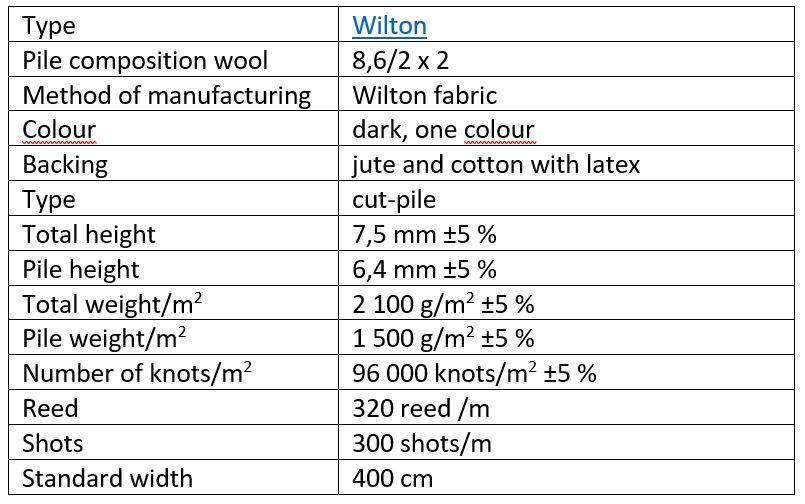

Place the DUT in the center of a carpet placed on a standard hard floor.3 The EN 60704-2-1:2014 standard defines that the size of the carpet used should be 1 m × 1 m. The carpet should be a Wilton type carpet4 with the following specifications:

The DUT must be placed with a minimum distance of 1 m between any surface (including protruding parts) of the DUT and the nearest wall.

2) As referenced in EU Regulation 666/2013.

3) A standard hard floor has a sound absorption coefficient lower than 0,1 and an areal density of at least 50 kg/m2. A 5cm thick concrete floor should be suitable.

4) A Wilton type carpet is a carpet woven on a Jacquard loom with loops like a Brussels carpet but having the loops cut to form a close velvety pile.

Measuring the DUT noise level

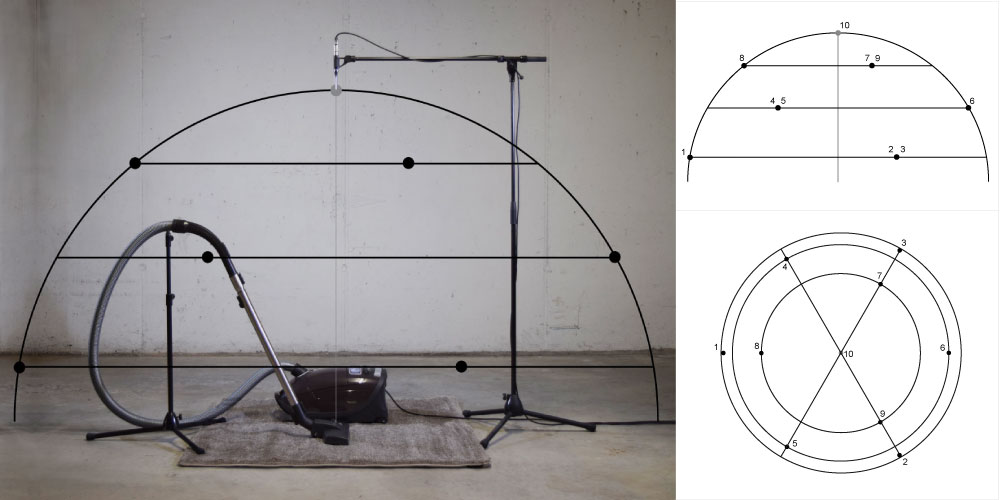

Position ten microphones along an envelope around the DUT (hemisphere configuration), each with a distance of preferably 2 meters and at least a minimum of 1.5 meters from the center of the carpet.

Switch on the DUT. At each of the ten determined measurement positions, measure and store the noise level5 for 30 seconds.

Click here for more about Frequency-Weightings for Sound Level Measurements.

5) LAeq is the sound level in decibels equivalent to the total A-weighted sound energy measured over a stated period of time.

Measurement Corrections

Choosing the Room

The reverberation test can be used only in a room that has approximately a cubic shape and is substantially empty. The room length and width should be each less than three times the ceiling height. The room temperature must be between 15 °C and 30 °C.

The Reverberation Test

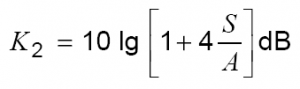

In the case where the DUT is positioned with one or more sound-reflecting surfaces nearby, measure reverberation time twice at each of three microphone positions. You will get 6 readings in total. The environmental correction for reverberation, K2, that can be subtracted from the measured noise level immission of the DUT, is calculated as

where

A is the equivalent sound absorption area, in square meters, of the room;

S is the area, in square meters, of the surface of the measurement hemisphere.

A is calculated using the Sabine reverberation time equation:

where

V is the volume, in cubic metres, of the test room;

Tn is the measured reverberation time in seconds.

The Residual Background Noise Test

At each of the ten determined measurement positions, measure and store the background noise level for 30 seconds. This environmental correction for background noise, K1, can be subtracted from the noise level measured from the DUT.

It is recommended to leave the room during measurement so that any noise generated by the operator will not affect the measurement.

Click here for more on how to measure!

What do I have to consider when documenting the sound power measurement results?

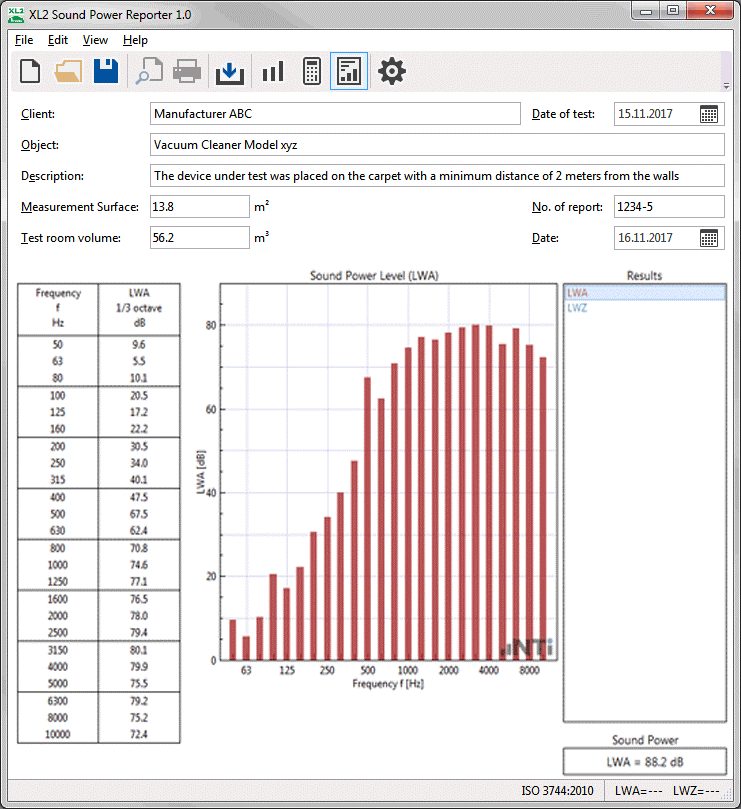

There are a few very good software programs that support the calculation, evaluation and visualization of the data and provide the ability to create a measurement report. The software solution you choose must also allow for correction calculations (background noise and room reverberation correction).

Here’s an example:

The following should be included in the measurement report:

- Description of the device under test including the age, condition, and history of the product

- Description of the measurement environment

Links relevant to this topic:

Household and similar electrical appliances – Test code for the determination of airborne acoustical noise:

The EU Regulation 666/2013 at a glance!

This Regulation establishes eco-design requirements for the placing on the market of electric mains-operated vacuum cleaners, including hybrid vacuum cleaners.

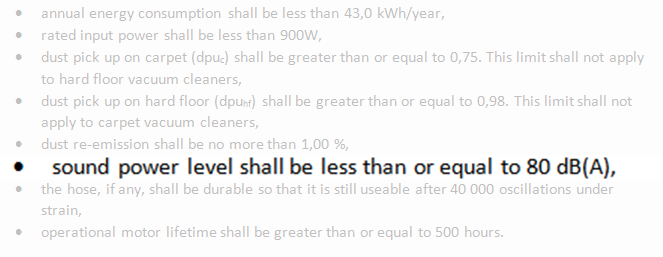

As from 1 September 2017, vacuum cleaners shall comply with the following requirements:

- annual energy consumption shall be less than 43,0 kWh/year,

- rated input power shall be less than 900W,

- dust pick up on carpet (dpuc) shall be greater than or equal to 0,75. This limit shall not apply to hard floor vacuum cleaners,

- dust pick up on hard floor (dpuhf) shall be greater than or equal to 0,98. This limit shall not apply to carpet vacuum cleaners,

- dust re-emission shall be no more than 1,00 %,

- sound power level shall be less than or equal to 80 dB(A),

- the hose, if any, shall be durable so that it is still useable after 40 000 oscillations under strain,

- operational motor lifetime shall be greater than or equal to 500 hours.