A2B* (short for Automotive Audio Bus) is a digital network technology from AD (Analog Devices). It is designed to connect all audio devices and components within a car. The practical feature of A2B is that the connections are realized using a 2-wire, unshielded twisted pair (UTP) cable. This provides a big reduction in weight and complexity of cable harnesses. The 2-wire A2B interface provides power supply, network control, as well as bidirectional high-quality digital audio on multiple channels.

One typical A2B device I see frequently in my daily work are microphone modules with an A2B interface. These modules contain an array of, for example, three or four digital MEMS microphones. The module is usually located in the vicinity of the central overhead panel. This allows directed listening (beamforming) in a hands-free communication application.

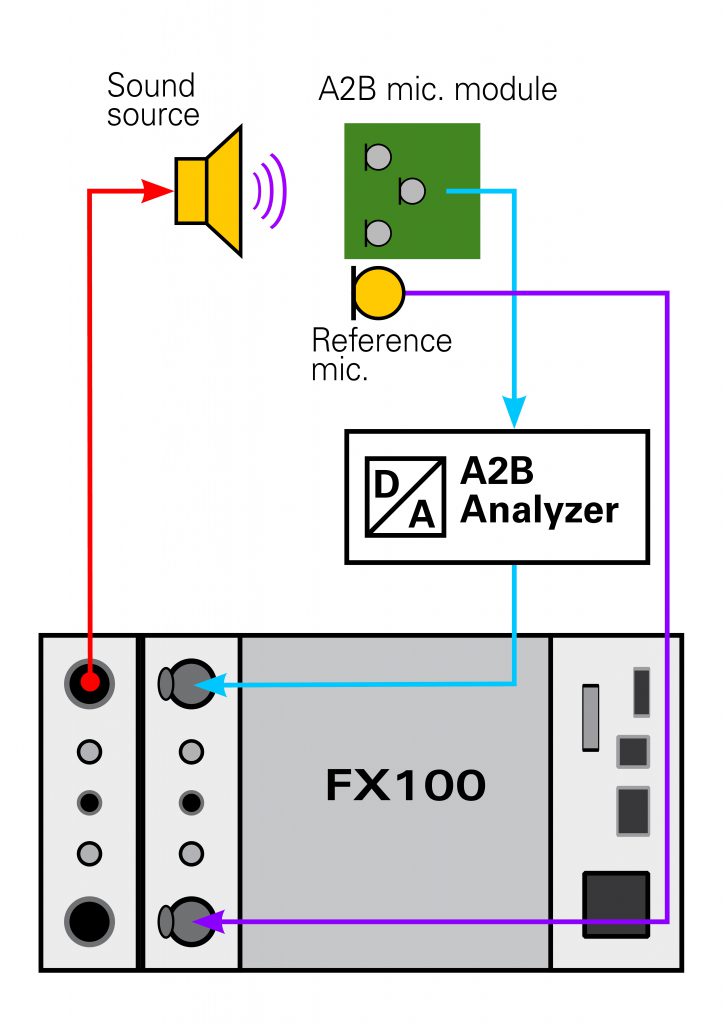

The A2B interface definition is proprietary. To get access to the audio data, in order to test the quality of the microphone array, for example, a device is required that decodes the A2B network data to either analog or AES/EBU digital audio format. The decoded audio channel signals (e.g. of the digital MEMS microphones) can then be routed to the audio analyzer for the testing. There are a few such decoding devices commercially available. They are programmable and can be integrated into existing microphone test systems.

A2B Analyzer from Mentor Automotive

Once the audio signal is accessible to the audio analyzer, the measurement tests for digital MEMS microphone arrays are performed.

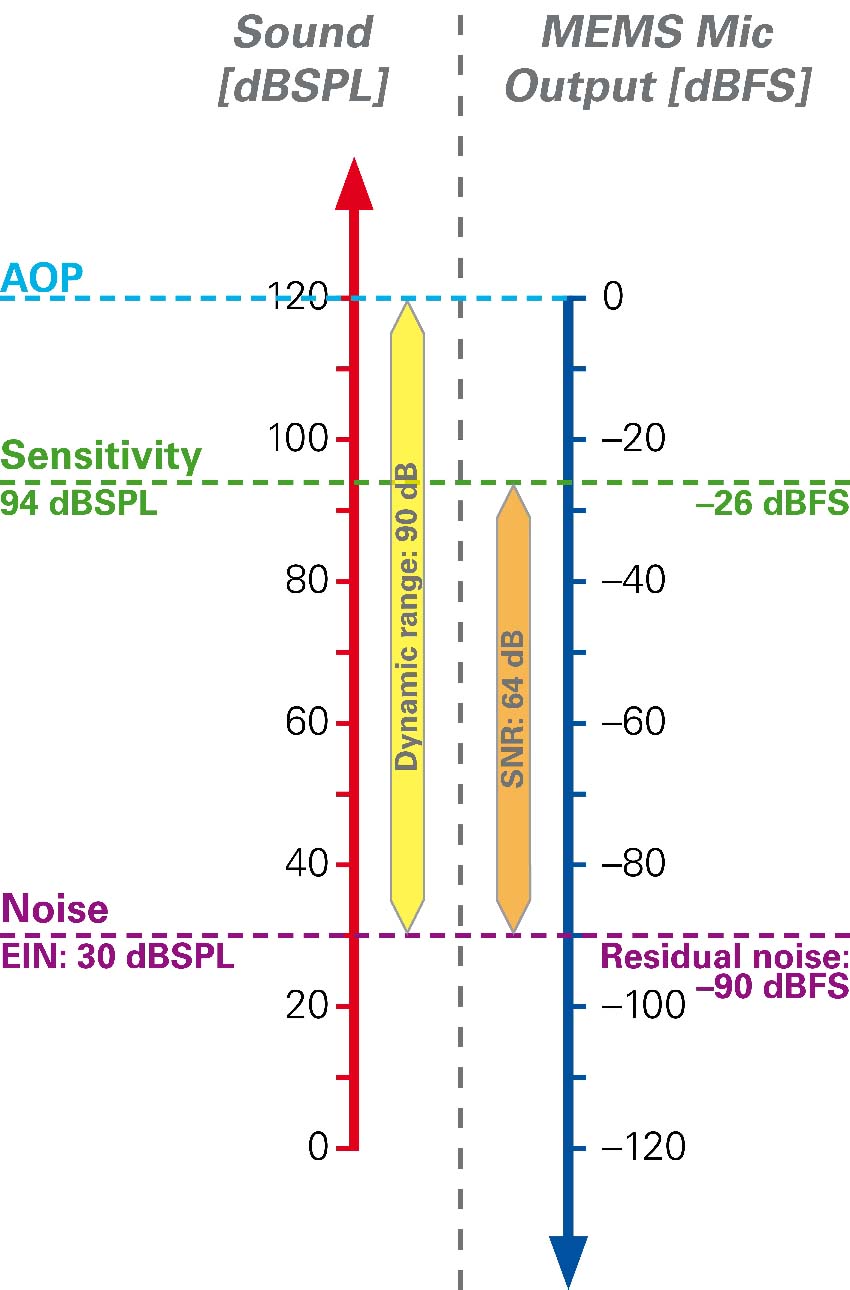

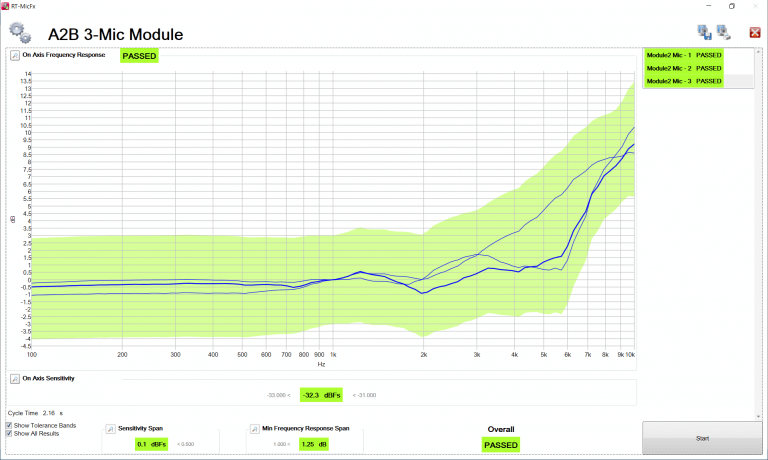

The typical parameters of interest for a QC test are Sensitivity, Frequency response, Distortion, and sometimes Signal to Noise ratio (SNR). For a complete microphone characterization, typically performed in a lab environment, parameters such as EIN (Equivalent Input Noise), and Dynamic Range are measured or calculated. Optionally, the directional behavior of a microphone at different frequencies can be measured by using a turntable.

For all absolute measurements (those that are not expressed in % or dB) the unit for digital MEMS microphones is dBF. This stands for “decibels below Fullscale” and describes the headroom of a digital microphone from 94dBSPL (1Pa) to the maximum digital output of that microphone. This point of maximum digital output is also referred to as the AOP (Acoustic Overload Point).

Acoustic vs. Digital Domain

For characterizing the performance of the complete A2B microphone module, it is of interest how the assembled MEMS microphones behave relative to each other. A typical parameter is the “Sensitivity Span”; the difference between the highest and lowest sensitivity measured on the assembled MEMS microphones.

Digital MEMS microphone peculiarities

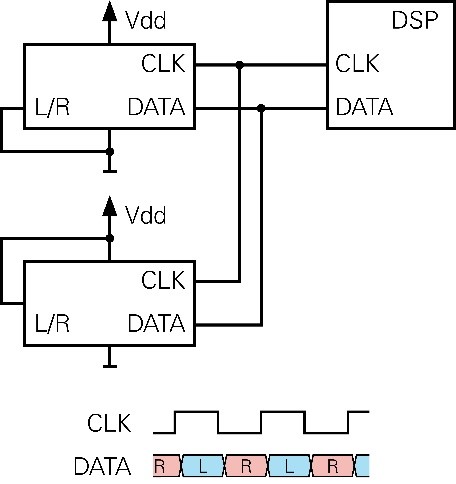

Digital MEMS microphones deliver data in the ½ cycle PDM format. The microphone requires a CLK input, and delivers its data on a DATA output. Furthermore, two microphones share one data line. Therefore, each microphone is configured to be either a “left” or “right” microphone. This is done by hardwiring the L/R input pin to either Vdd or ground.

In normal operation, the “left” microphone writes a data bit on each rising edge of the clock signal, while the “right” microphone writes a data bit on each falling edge. While one microphone is writing data, the other one puts its DATA output into a high-impedance mode. On the A2B codec that is receiving the data, the left and right signal data are then separated and put together into two signal streams.

Normal operation of two digital MEMS microphones

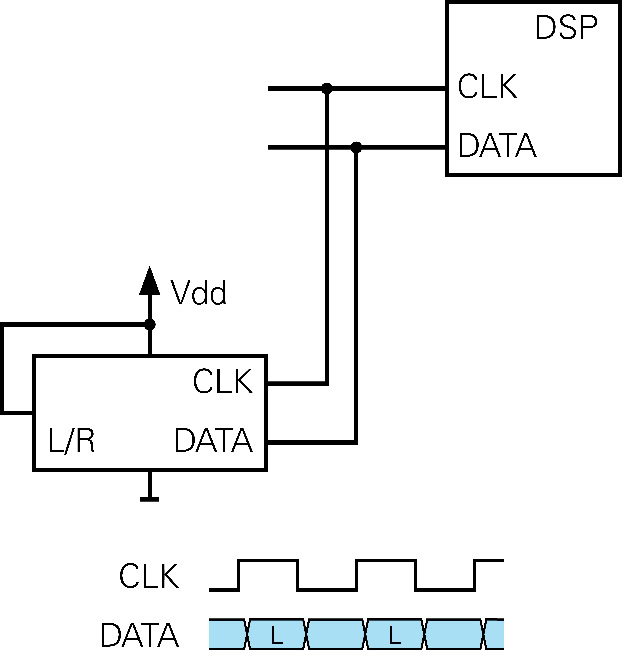

But what happens when one of the two microphones is not assembled correctly or is missing?

Operation with one inoperative or missing MEMS microphone

In this example, the right microphone is missing. Therefore, only the left microphone is writing to the data line. At the falling edges, the left microphone puts its DATA line to a high-impedance state. Therefore, the DATA line keeps its state as it was previously written by the left microphone. As a result, from the receiving A2B codec perspective, the right microphone seems to deliver exactly the same data as the left microphone. The two data streams are identical! This problem must be addressed by the microphone test system, as detecting a missing microphone is a fundamental duty when testing an A2B microphone module.

A2B module test system overview

The basic measurement system for testing an A2B microphone module array consists of an audio analyzer, an A2B decoder, a reference loudspeaker and a reference microphone. A PC software typically controls such a system.

A2B Mic Module QC software

*A2B is a registered trademark of Analog Devices Inc.